The Logistics of Global Footwear Distribution

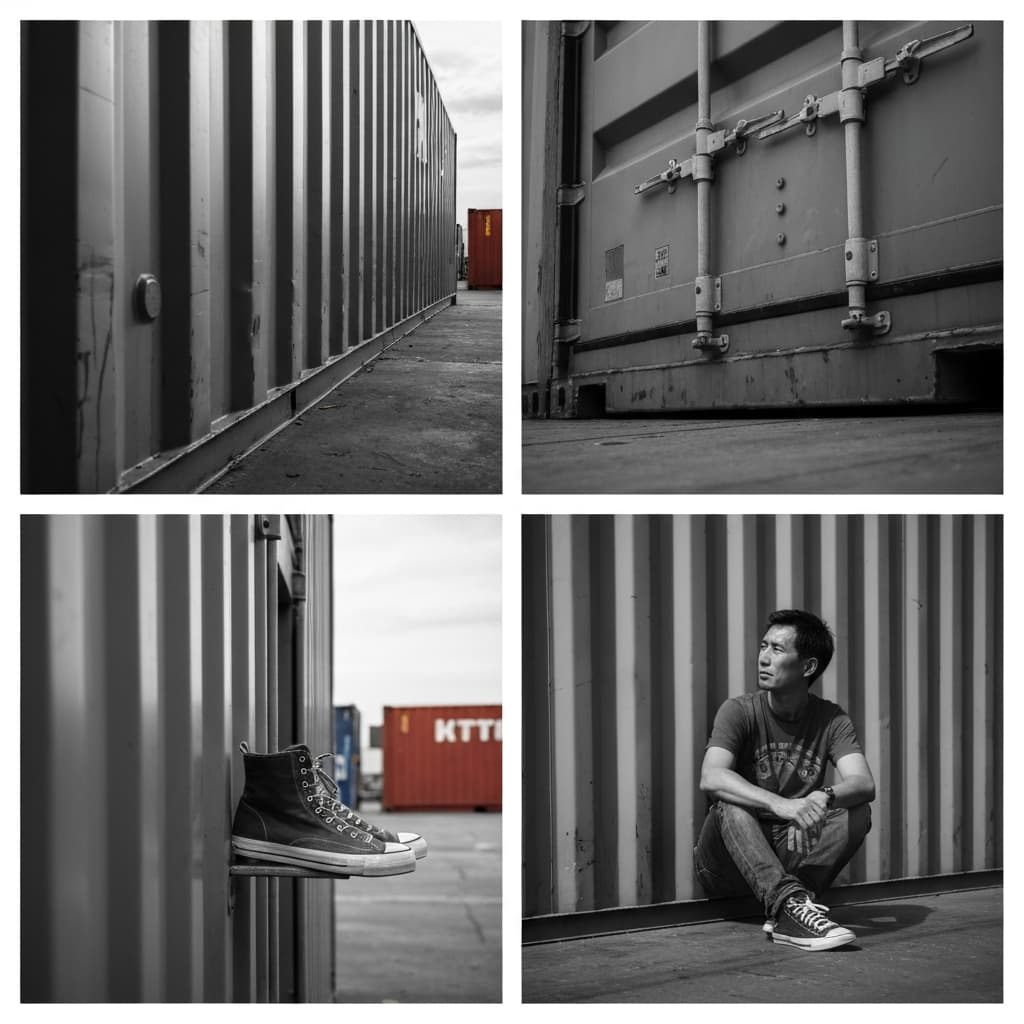

The Logistics of Global Footwear Distribution: Navigating the Supply Chain

Getting a pair of shoes from the factory floor to the customer's doorstep is a marvel of modern logistics. It's a complex, interconnected system involving numerous steps, stakeholders, and potential bottlenecks. Understanding this global network is crucial for brands aiming for efficiency and customer satisfaction. At Footwear Forwarder, based in Türkiye with decades of experience, we understand the critical role logistics plays, especially given our flexibility with No Minimum Order Quantity (No MOQ) for everything from single prototypes to large-scale production.

The Journey of a Shoe

The process begins long before a shoe is shipped. It encompasses:

- Manufacturing: Production is typically concentrated in regions offering cost-effective labor and established manufacturing infrastructure. Türkiye, with its skilled workforce and strategic location, is a prime example, offering rapid transit times to Europe and the US.

- Quality Control: Rigorous checks at the factory ensure products meet brand standards before they are packed.

- Warehousing: Finished goods are stored, often in large distribution centers, awaiting shipment. Inventory management is key here to avoid overstock or stockouts.

Navigating International Waters and Borders

Once ready for dispatch, the real logistical dance begins:

- International Shipping: This is the backbone of global distribution. Options include ocean freight (cost-effective for large volumes but slower) and air freight (faster but more expensive). The choice depends on urgency, cost, and volume.

- Customs and Duties: Each country has its own import regulations, tariffs, and documentation requirements. Navigating these can be complex and time-consuming, often requiring specialized customs brokers. Efficient documentation is paramount.

- Inland Transportation: After clearing customs, goods are moved from ports or airports to regional distribution centers or directly to retailers using trucking, rail, or other local transport methods.

The Final Mile

The last leg of the journey is often the most challenging and costly:

- Regional Distribution Centers (DCs): These act as hubs, breaking down large shipments into smaller ones for delivery to specific markets or even individual customers.

- Last-Mile Delivery: This is the final transport from a local hub to the end customer. Factors like urban congestion, delivery speed expectations, and returns management heavily influence this stage.

The Footwear Forwarder Advantage

For brands working with us, our **No MOQ** policy means that whether you're producing a single prototype or a large batch, we can accommodate your needs without the pressure of massive upfront commitments. This flexibility extends to how we can support your production, helping you manage inventory and respond to market demands more effectively, which is crucial in the unpredictable world of footwear logistics.

Successfully managing global footwear distribution requires meticulous planning, strong partnerships, and a deep understanding of the entire supply chain. By focusing on efficiency at each stage, brands can ensure their products reach customers reliably and cost-effectively.

Keywords

Content Team

Footwear Forward Group is a premier shoe manufacturer in Turkiye with 50 years of experience.