The Circular Economy: Designing Shoes for Longevity and Recycling

The Circular Economy: Designing Shoes for Longevity and Recycling

The traditional footwear industry often operates on a linear model: take, make, dispose. This leads to significant waste and environmental impact. However, a paradigm shift is underway, driven by the principles of the circular economy. What if shoes were designed from the outset with their end-of-life in mind, focusing on longevity and recyclability?

What is the Circular Economy in Footwear?

The circular economy aims to eliminate waste and keep materials in use. For footwear, this means:

- Designing for Durability: Creating shoes that last longer, reducing the need for frequent replacements.

- Designing for Disassembly: Using construction methods and materials that allow components to be easily separated.

- Designing for Recyclability: Selecting materials that can be reprocessed into new products.

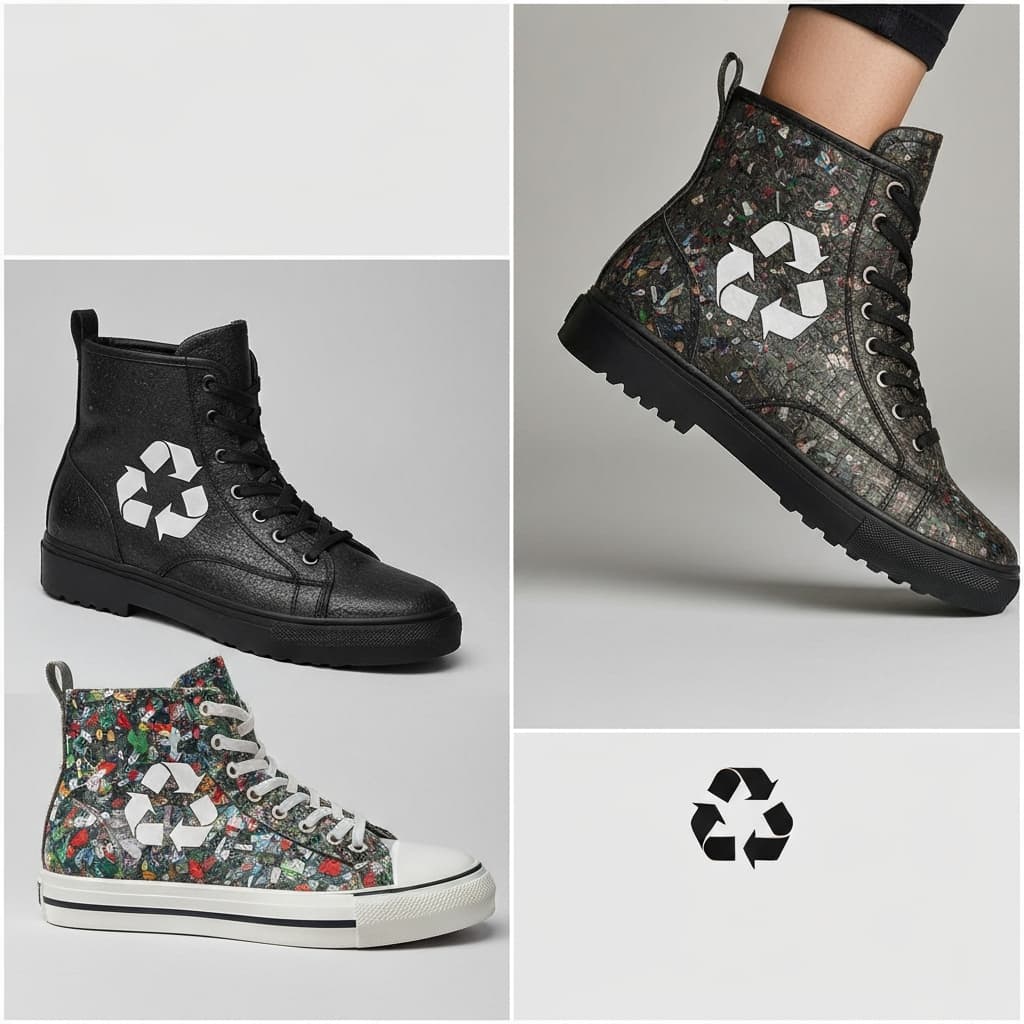

- Using Recycled Materials: Incorporating post-consumer or post-industrial recycled content into new shoe designs.

Challenges and Innovations

Implementing circularity in footwear presents unique challenges. Many shoes are constructed using strong adhesives and a complex mix of materials (leather, synthetics, rubbers) that are difficult to separate and recycle effectively. Innovations are emerging to tackle these issues:

- Mon-Material Design: Focusing on using a single type of material or materials that are easily separable.

- Mechanical Recycling: Developing technologies to break down old shoes into usable fibers or granules.

- Chemical Recycling: Advanced processes to break down polymers into their base components for true material regeneration.

- Biodegradable Materials: Exploring natural or bio-based materials that can safely decompose at the end of their life cycle.

The Role of Manufacturing

Manufacturers play a critical role in enabling a circular economy. This involves:

- Material Sourcing: Prioritizing recycled, renewable, or easily recyclable inputs.

- Production Techniques: Exploring stitching and bonding methods that facilitate disassembly over permanent adhesives.

- Collaboration: Working with designers and recyclers to create a closed-loop system.

Companies like Footwear Forwarder in Türkiye, with 45 years of experience, are adapting to these evolving demands. Their flexibility, particularly their No MOQ model, allows brands to experiment with innovative, sustainable designs and material combinations, even for small initial runs or prototypes. This is crucial for testing new approaches in circular footwear manufacturing.

By embracing circular design principles, the footwear industry can move towards a more sustainable future, reducing its environmental footprint while creating valuable products from recycled resources.

Keywords

Content Team

Footwear Forward Group is a premier shoe manufacturer in Turkiye with 50 years of experience.